-

- Brands

- Industries

- All industries

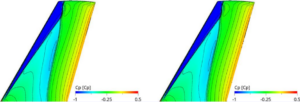

- Aerospace & Defense

- Architecture, Engineering & Construction

- Business Services

- Cities & Public Services

- Consumer Packaged Goods & Retail

- High-Tech

- Home & Lifestyle

- Industrial Equipment

- Infrastructure, Energy & Materials

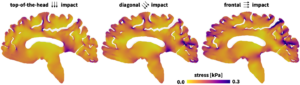

- Life Sciences & Healthcare

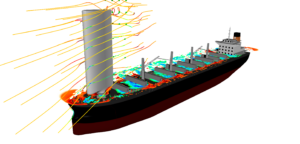

- Marine & Offshore

- Transportation & Mobility

- Topics

Subscribe

Register here to receive a monthly update on our newest content.